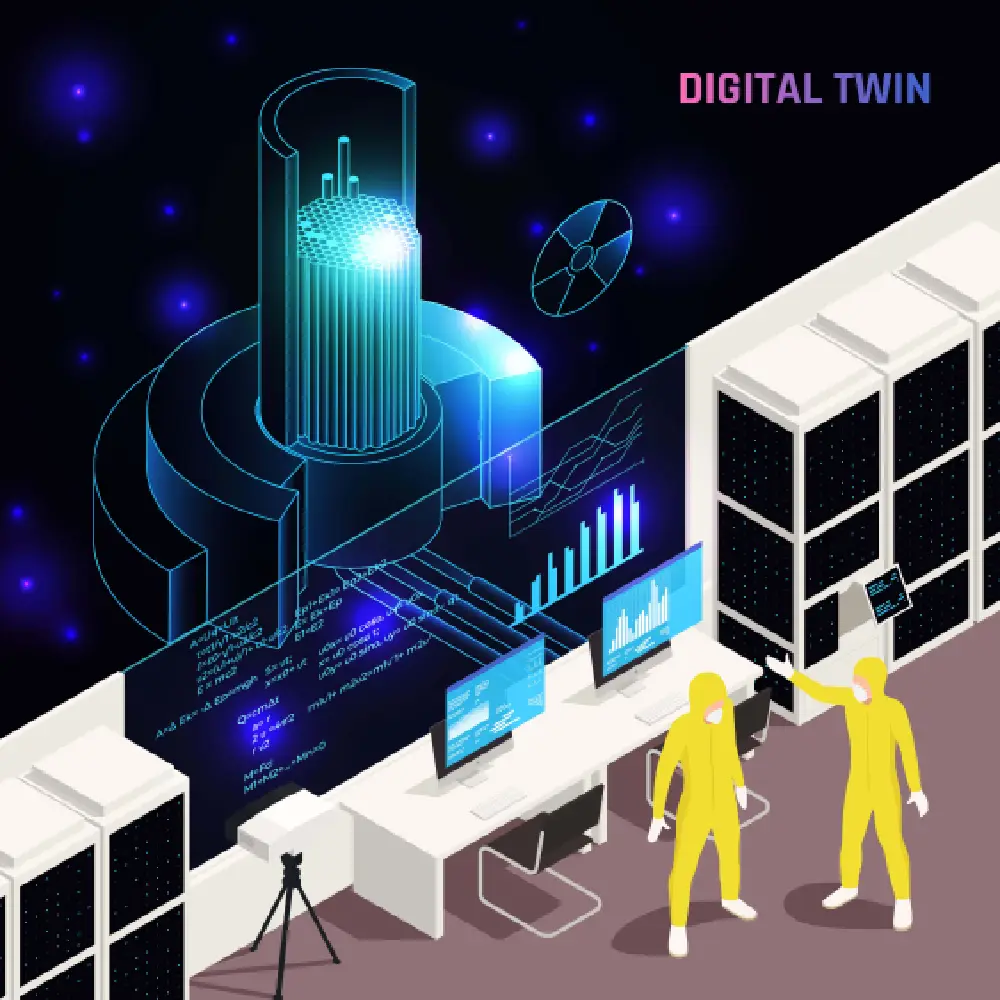

The chemical manufacturing industry is like a powerhouse. As it got a market size that goes beyond $4 trillion and supports millions of jobs around the world. But it is also grappling with some tough challenges. We are talking about high operational costs, strict regulations, and the constant need for precision in those intricate processes. This is where digital twins come into play. Consider them as a digital copies of physical systems, and when you throw in artificial intelligence, you have got a game-changer. These digital twins are shaking things up in chemical manufacturing by making everything more efficient, safer, and more sustainable.

AI-driven digital twins are opening the way for the future. In this article, we are diving into their transformative effects, and we have got something for everyone, industry pros and all the science buffs out there curious about what’s brewing in Industry 4.0.

What Are AI‑Driven Digital Twins?

A digital twin is a virtual model of a physical asset, process, or system, aligned with real-time data to mirror its real-world behavior. Digital twins in chemical manufacturing may be a whole plant, a piece of equipment (such as a reactor), or even a supply chain. AI in the chemical industry takes these twins a notch higher by incorporating predictive analytics, pattern recognition, and improvement algorithms. As an example, AI may be used to process sensor data and forecast equipment malfunctions or adjust production settings, which is necessary in the industry of precision and regulatory demands. It is this synergy that makes digital twin’s applications in chemical plants a must-have in the contemporary manufacturing.

1. Core Components of a Digital Twin

A digital twin in the world of chemical manufacturing is basically like a live, virtual representation of a physical asset or process. It integrates:

- Sensors and loT: Gather real time data of physical assets, i.e., temperature or pressure values.

- Cloud Platforms: Store and process large datasets, which makes them scaleable and easy to access.

- AI Models: The most intelligent parts of the operation, these highly complex algorithms, filter the data, find patterns, make predictions, and create insights. They can include machine learning, deep learning, and advanced analytical models.

2. How AI Adds Intelligence to the Twin

AI changes the game when it comes to digital twins. They go from being just lifeless copies to these clever decision-makers. AI can actually analyze a ton of data and make precise decisions, after these steps:

- Pattern Recognition: Find trends in data, such as recurring inefficiencies in a production line.

- Anomaly Detection: Spot potential issues, like unusual vibrations in a pump, before they cause failures.

- Optimization: Real time manipulation of process factors to improve product and reduce wastes.

Why Chemical Manufacturing Needs Digital Twins Now

AI-powered digital twins are changing the way in smart manufacturing, especially in the chemical sector. They handle some big issues, like those pesky high costs and the need for highly precise operations. So, let’s take a look at a few reasons why they’re becoming such a key part of Industry 4.0 in chemical manufacturing.

1. Predictive Maintenance for Reduced Downtime

Predictive maintenance in the chemical industry is really a game changer. Digital twins use AI to sift through real-time data from sensors. This technology can actually predict when equipment might fail before it happens. Take a pump, for example. A digital twin can keep an eye on things like vibrations and temperature. If something is wrong, it will let the maintenance team know so they can plan repairs ahead of time.

This proactive approach is a big deal; it cuts down on those surprise downtime that can hit chemical plants hard, sometimes costing them millions every year. By keeping things running smoothly, these predictive maintenance strategies really boost reliability and efficiency in operations.

2. Real-Time Process Optimization

Using AI for process improvement with digital twins is fascinating. It’s all about making those constant adjustments to keep everything running at its best. So, here’s how it works: AI dives into data from sensors and control systems, and it can fine-tune things like temperature or flow rates to really boost output.

For example, a digital twin of a reactor can simulate various conditions to find the ideal settings for maximizing yield while reducing energy use. This kind of precision is crucial, especially in manufacturing. I mean, even the tiniest inefficiencies can end up costing a lot in the long run. So, having that level of detail really makes a difference!

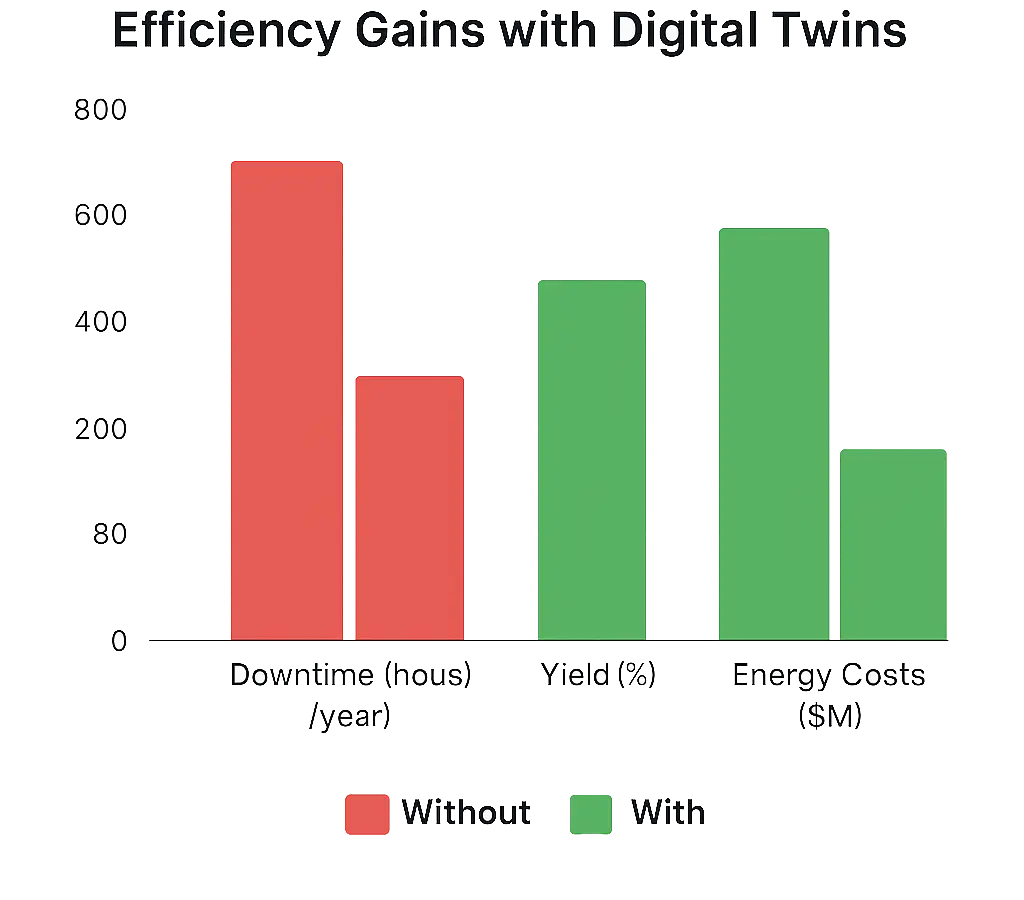

3. Driving Significant Cost Savings

When it comes to the chemical industry, using predictive maintenance and real-time optimization really are highly beneficial. We’re talking about some serious cost savings here. By cutting down on downtime, using raw materials more efficiently, and tweaking energy consumption, digital twins can deliver a pretty impressive return on investment.

In fact, there’s a study from McKinsey that suggests digital twins might be capable of reducing maintenance costs by as much as 10%. Moreover, they can boost the effectiveness of the equipment by about 5-10%. These figures really matter in an industry where margins are tight and regulatory expenses can be sky-high.

Beyond Efficiency: Enhancing Safety, Sustainability, and Innovation

Undoubtedly, manufacturing efficiency is very important. However, AI-driven digital twins bring a lot more. They can make a real difference when it comes to safety, sustainability, and innovation. These are huge priorities for the chemical industry today. It’s not just about cranking out products faster; it’s about doing it in a way that’s safer and better for the world.

1. Enhancing Plant Safety and Risk Management

Safety is very important in chemical manufacturing. The risks can significantly increase when we are dealing with hazardous materials and all these complicated processes. That’s where digital twins come into play. They let operators simulate dangerous situations—think chemical spills—without any real-world consequences.

Take a toxic gas leak, for example. A digital twin can actually model how that gas might spread, and that helps in figuring out the best ways to contain it. Additionally, with real-time data flowing in, operators can catch risks right away. Like, if there’s overheating in a reactor, they’ll know about it instantly. This not only keeps everything compliant with safety regulations, but it also keeps the workers safe.

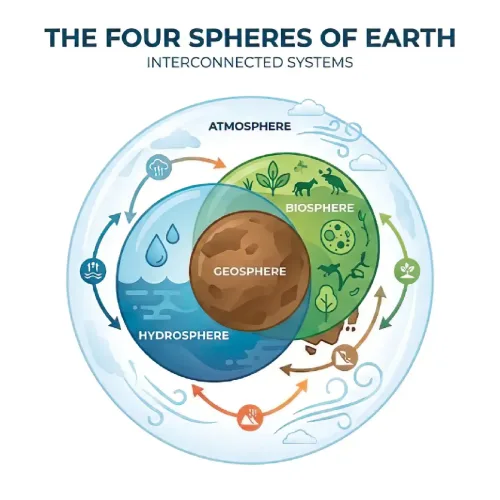

2. Driving Sustainable Chemical Production

Sustainability is becoming super important these days, especially in the chemical industry, which is feeling the heat to cut down on its environmental impact. One cool way they are doing this is through digital twins. Basically, these high-tech models help companies use their resources more efficiently, which means less waste and lower emissions.

Digital twins can actually simulate different production scenarios to figure out how to cut back on water or energy usage. Furthermore, with real-time emissions tracking, companies can stay on top of environmental regulations and make sure they’re in line with circular economy principles.

| Year | Waste (Tons) | Emissions (CO2 Tons) |

|---|---|---|

| 2020 | 10,000 | 50,000 |

| 2023 | 7,500 | 40,000 |

3. Accelerating Research & Development

AI applications in industrial chemistry shine in research and development (R&D). Digital twins could be used to test new chemical reactions, formulations, or processes virtually, limiting the number of expensive physical experiments. As another example, a digital twin could model the behavior of a new catalyst in different conditions, accelerating innovation cycles. This feature lowers research and development expenditures and decreases time to market, providing an organization with a competitive advantage.

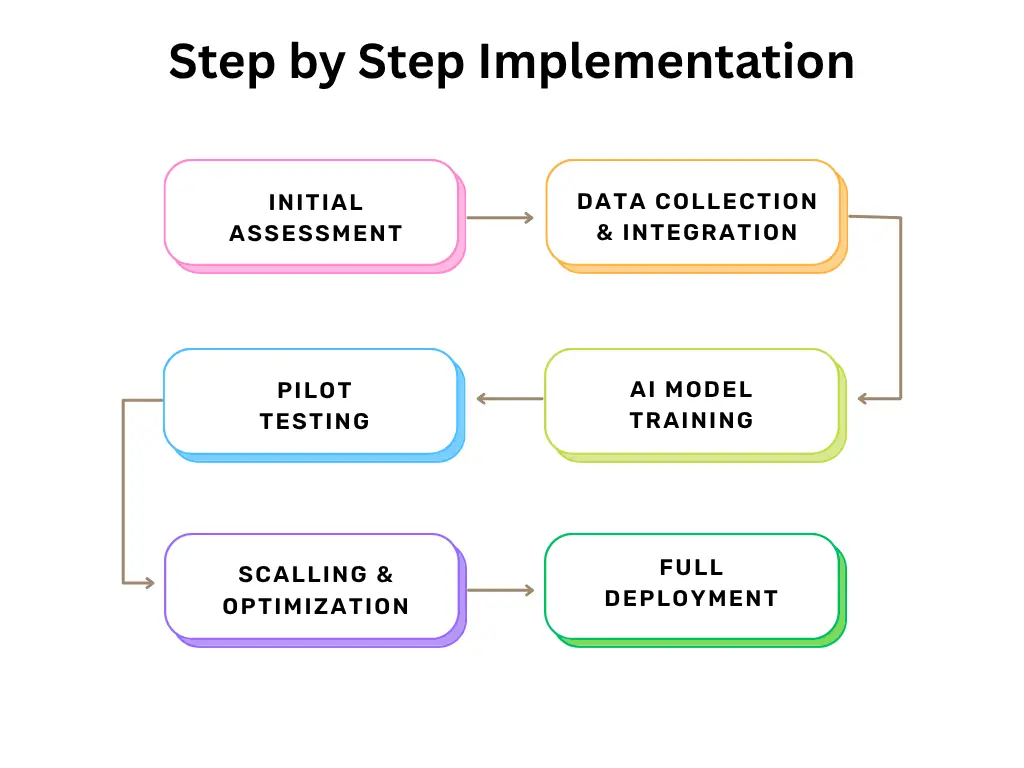

Tools, Platforms & Practical Tips

If you want to really get into optimizing chemical plants with AI using digital twins, you’ve got to have the right tools and strategies in place. There are some top-notch platforms out there that can help with this. Let’s take a look at a few of them:

- Siemens Digital Industries Software has really got a full package going on. They’ve got tools like Process Simulate and Plant Simulation, which are perfect for setting up and analyzing digital twins of whole production systems.

- Then there’s AVEVA. They’re well-known in the industrial software scene, providing solid solutions for things like process simulation, asset performance management, and operations control.

- AspenTech: They focus on process optimization software specifically for the chemical industry. Their tools are designed to mesh well with digital twins, which means you get some pretty advanced analytics and control. It’s all about making things run smoother.

Key Considerations Before Adoption

- Data Quality: Guarantee precise, reliable sensor data.

- Integration: Connect digital twins with existing IT/OT systems.

- Team Training: Equip staff with skills to leverage digital twin insights.

Common Pitfalls to Avoid

- Overengineering: Avoid overly complex models that are hard to keep up.

- Lack of Stakeholder Buy-In: Engage all teams to guarantee adoption.

- Ignoring Scalability: Plan for future growth to avoid rework.

Conclusion: The Future Is Smart, Predictive, and Efficient

AI-driven digital twins are not just some fancy technology upgrade. They are actually a whole new way of thinking about chemical manufacturing—smarter, quicker, and a lot safer. When you bring together predictive maintenance, process simulation, and automated optimization, it’s like giving manufacturers a powerful toolkit. This innovation really helps them keep up with the competition, meet regulations, and be more sustainable, too.

Are you excited about diving into the future of digital twins in chemical manufacturing? A great way to get started is by launching a pilot project. Just get that first momentum going, and then let the data lead the way to your success.

Additionally, while we’re on the topic, what other industries do you think could really take advantage of AI-powered digital twins? I’d love to hear your thoughts! Feel free to drop a comment below.